Digital twins in construction: Smarter, safer, and more profitable projects

The construction industry has been slowly awakening to embrace the need for digitalisation. Digital transformation is a reality and the built asset industry can benefit from it in several ways. Out of the digital tools that are leading the change, one of the most complex and useful technologies is that of digital twins. These virtual models replicate physical assets in real time, helping teams build smarter, faster, and more efficiently and with higher quality.

But what exactly is a digital twin—and why does it matter for your business?

What is a digital twin?

A digital twin is a dynamic, real-time virtual representation of a physical asset, system, or process. It is not just a 3D model or a visual rendering. Unlike a simple visual model, a true digital twin is continuously updated with live data from the real-world counterpart, creating a synchronized digital environment that evolves over time.

You can also think of a digital twin as a “living” dynamic replica of your building or infrastructure project: it is fed information by sensors and data, and it is capable of simulating performance, spotting issues, and informing decisions throughout the lifecycle of a built asset.

The impact of digital twins in construction

Construction projects are notoriously complex and high-risk. Even the best managed sites are at risks of dealing with delays, cost overruns, rework, and safety concerns.

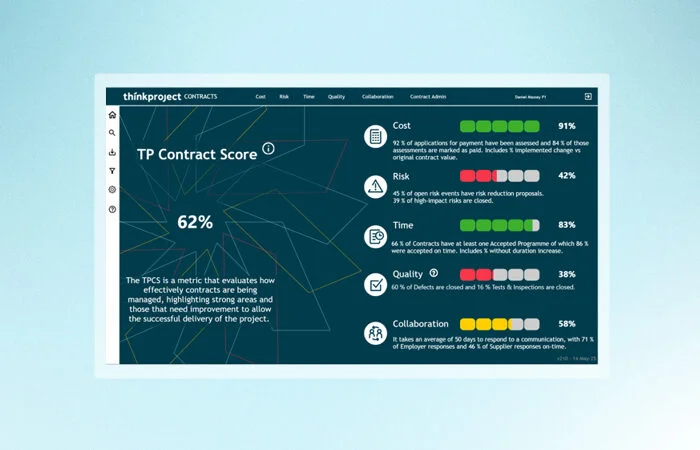

Data is a highly valuable asset in construction and it can be used to optimise projects and enable data-driven decisions. However, data is often siloed across various teams and tools, and decisions are made with incomplete or outdated information.

Digital twins tackle these challenges head-on by offering:

- End-to-end visibility across the project lifecycle.

- Smarter decision-making based on real-time and predictive data.

- Operational efficiency by bridging the gap between design, construction, and facility management.

Key use cases for digital twins in construction

While it is important to note the benefits that digital twins have been designed for, the value lies in how they can be used in real-life scenarios. Let’s have a look at the most common use cases:

1. Design Optimization

Digital twins allow you to simulate how a structure will perform in the real world. You can test energy efficiency, lighting, airflow, and structural resilience under various scenarios—long before you pour a single cubic meter of concrete.

This capability allows for early design decisions that reduce rework and enhance sustainability, while aligning stakeholders with a shared, data-backed vision.

2. Construction monitoring and progress tracking

As more businesses are embracing digitalisation, they are also embracing using more and more digital tools. Technologies such as IoT sensors, drones, and cameras can feed real-time data into a digital twin. Project managers can then monitor progress down to individual components. You’ll know what’s been installed, what’s delayed, and where bottlenecks are forming—without setting foot on-site.

3. Safety and Risk Management

Digital twins also help model safety scenarios, identify high-risk zones, and simulate emergency responses. Combined with AI, the twin can even predict risks before they materialize—like equipment collisions, worker fatigue, or unstable structures. In short, they help you move from reactive to proactive safety management.

4. Lifecycle Asset Management

Once construction is complete, the digital twin becomes a long-term asset. Facility managers can use it to monitor energy use, schedule predictive maintenance, and simulate the impact of upgrades or repurposing.

5. Sustainability and Compliance

As sustainability is becoming a business imperative, digital twins allow you to track emissions, material usage, and energy consumption in real time. They also support compliance with environmental regulations and green building certifications. This is good both for the planet, and your business.

How to get started with digital twins

While anything that contains the world “digital” may at first sound difficult to embrace, adopting digital twins doesn’t require a massive overhaul or overnight transformation. It starts with a few key steps that align strategy, technology, and culture.

1. Assess Your Digital Maturity

Start by evaluating where your organization currently stands. Are you already using BIM? Are you using a CDE? Do you have IoT-enabled assets or cloud-based data systems? A digital twin builds on these foundations, so understanding your readiness is step one.

Starting from scratch is not a problem either. You can start with a pilot project and scale from there.

2. Align Stakeholders Early

While a digital twin is a great tool, its usage spans multiple teams: design, construction, operations, IT, and finance. The tool itself is limited in capabilities unless it is properly used by all stakeholders.

Getting these groups on the same page early is critical. Define clear objectives: Are you focused on cost savings, safety, or asset performance? When everyone understands the “why,” adoption is smoother—and ROI comes faster.

3. Choose the right technology partners

There’s a growing ecosystem of tools and platforms that support digital twin creation and management. When choosing the right one for your business, make sure to check:

- Compatibility with your existing BIM and IoT tools

- Real-time data integration

- Scalability across projects and asset types

- Strong user support and security standards

4. Start small, scale smart

You don’t need to have everything set up on day one. Instead, plan for a gradual adoption. Start with a pilot project—perhaps a high-value building or a complex infrastructure asset. Use that to validate the technology, demonstrate ROI, and build internal advocates.

Digital twins are more than just a technology trend—they’re a strategic tool that helps construction firms deliver smarter, safer, and more profitable projects. From early design through to long-term operations, they enable real-time insight and data-driven decision-making that sets leaders apart in a competitive market.

If you’re looking to reduce risk, optimize performance, and build a foundation for the future, digital twins aren’t just an option—they’re an opportunity.

Within the Thinkproject Built Asset Lifecycle Platform, you can create and manage digital twins. The platform provides this capability, as well as its integration with various solutions.

Learn more about our platform or get in touch with our experts to explore what a digital twin could look like for your next project.